11 Dec

Economic Order Quantity Calculator

The economic order quantity calculator is a simple calculator to compute the economic or optimal quantity of goods or services that a business requires ordering.

A business should always try to reduce their costs as much as possible. It is always a good practice to maximize your profits. Read further to get more knowledge about what is EOQ, how to use an economic order quantity calculator, simple EOQ formula, some examples related to economic order quantity calculator. Also learn about how an EOQ can improve your inventory management.

What is Economic Order Quantity?

Economic order quantity (EOQ) is the standard order quantity that a company should gain to reduce inventory costs, including holding costs, shortage costs, and order costs. The EOQ is the world’d most used classical setup for manufacturing scheduling.

How EOQ model operates?

When products are being ordered in, and don’t use it immediately, rather you hold the goods in your warehouse, it costs you money, therefore, holding cost. But the case here is, if you don’t do so, you may lose customers if you run out of stock. Therefore, to maximize profits, you need to keep a balanced inventory with as fewer costs as possible. This may be difficult – but EOQ is a boon!

Here, you can take help of EOQ to calculate what quantity of inventory you should keep reducing your inventory costs. However, the EOQ assumes that there are costs related to products ordering and holding in the inventory. The economic order quantity calculator helps you to reduce these costs to the lowest they can be.

All credits to the economic order quantity formula, you can easily predict the orders required to keep your optimal quantity of inventory managed. The result value from the economic order calculator tells you the number of quantity you should order in your inventory to reduce the ordering and holding costs.

EOQ not only helps you in efficient inventory management, but also aid in managing your company’s cash flow. The reason is, there are many companies for which inventory costs directly affect their balance sheet. Minimizing the ordering and holding costs will improve the cash flow.

Use our economic order quantity calculator and keep your inventory optimized to increase your firm’s profitability! The EOQ calculator may give you a great boon in your business.

How to calculate EOQ?

We calculate EOQ based on many assumptions, which includes:

- The ordering cost always remains the same.

- The purchase price always remains the same.

- Demand of the product is constant and so leads time.

- The size of the order may fluctuate, but the ordering costs remains same.

- Holding costs depend on the average inventory available.

- While calculation, there is only one product involved.

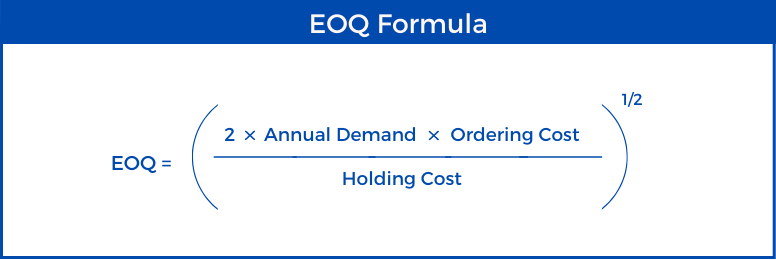

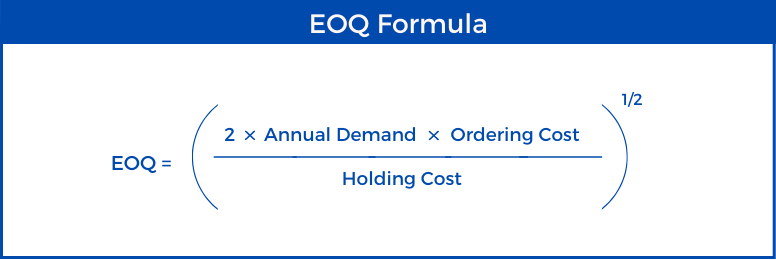

Formula used in Economic Order Quantity Calculator:

We employ the formula below to calculate EOQ:

Economic Order Quantity (EOQ) = (2 × D × S / H) 1/2

Where:

- D represents the annual demand (in units),

- S represents the cost of ordering per order,

- H represents the carrying/holding cost per unit per annum.

Example:

A company expects sales of 20,000 units per year. What is the economic order quantity (in units) per order under the below conditions?

The ordering cost = $200 per order.

Holding cost = $100 per unit per year.

The formula to calculate EOQ is:

- EOQ = (2 × Annual Demand × Ordering Cost / Holding Cost) 1/2

- EOQ = (2 × 20,000 × $200 / $100) 1/2

- EOQ = (80,000) 1/2 = 400 units per order.

FAQs

Q1. Is EOQ (Economic Order Quantity) similar to ELS (Economic Lot Sizing) model?

Ans: EOQ (Economic Order Quantity) measure the amount of products that one should keep in the inventory to minimize the total variable costs, therefore, the sum of inventory holding or carrying cost and ordering cost for each stock keeping unit.

ELS (Economic Lot Size) refers to regular and continuous delivery of products rather than in batches.

For instance, if a company follows EOQ model, the delivery of 18 units are made in batches every third day with 6 units, whereas, in ELS model, 2 units are daily produced and delivered, so that the total 18 units are completed in 9 days.

Q2. Is it possible that the reorder point be greater than EOQ?

Ans: The reorder point is the point when you need to reorder inventory so you may not run out of stock. EOQ is a helpful cash flow tool that aids in determining the reorder point, yet sometimes this relationship can be complex.

Assume that a company reorders in short supplies frequently. Their ordering costs will increase and therefore are unfavourable when compared to EOQ. On the other hand, if they stop reordering depending on EOQ, it may introduce inventory shortage costs. Therefore, the money lost because of understock, and that means a business loss. The EOQ calculator formula assumes that there is a constant demand, supply, and holding costs, which is not probably to be the situation always.

When there is good demand, turnover, or any unexpected discounts for bulk ordering, the reorder point will be higher than the EOQ.

Q3. Are there any limitations of the EOQ formula?

Ans: Well, we won’t say limitations, rather consider them as hindrances. The assumptions involved in EOQ calculator formula curb the use of the same. It is not always necessary that the costs per unit of a purchase of an item will always remain the same. It changes from time to time. Further, it is necessary for the EOQ model that the demand remains constant all along the year. However, it is not possible. Demand of a product changes in customer’s preferences. Also, ordering cost per unit can’t be consistent as it includes transportation costs, which varies per transport.

Related Tools

Break-Even Point Calculator | Total Cost Calculator | Profit Margin Calculator